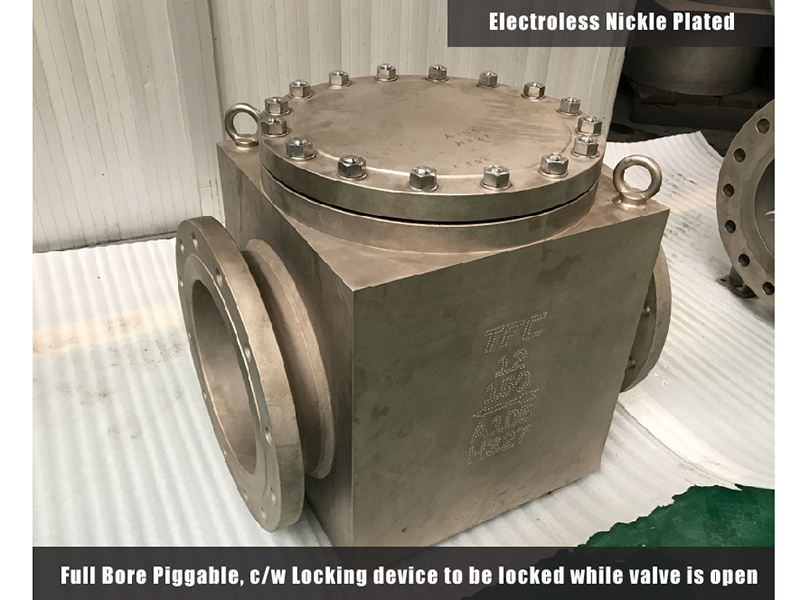

SUBSEA CHECK VALVE

Date:2019-09-05 Click:2332

Subsea Check Valve

Subsea valve is a general term for all valves applied to underwater pipelines. At present, the submarine valves are mainly concentrated in the underwater pipelines and pipelines of offshore oil and gas projects. At the same time, underwater valves also have certain applications on deep sea submersibles.

At present, the subsea valve is mainly a ball valve, a slab gate valve and a check valve. The operation mode mainly adopts hydraulic motion, ROV operation and manual operation (shallow water).

The design criteria for subsea valves are currently:

API 6DSS Subsea pipeline valves

API 17D Subsea Wellhead and Tree Equipment

The difference between the development of subsea valves and conventional valves is mainly the influence of external pressure resistance on wall thickness, the influence of submarine working conditions (such as ocean current, sea creatures, fishing nets) on the external structure of the valve, seabed anticorrosive coating, electrode corrosion, etc. . These companies are not only investing in a large number of personnel in the software design and development, but also investing in external pressure test chamber equipment, seawater corrosion test chambers and other special inspection and testing equipment.

Product Information

|

Design & Manufacture: |

API 6DSS |

|

Face to Face: |

ASME B16.10 |

|

End Dimensions: |

ASME B16.5 |

|

Pressure & Temperature: |

ASME B16.34 |

|

Test & Inspection: |

API 6DSS |

Other Information

|

Type: |

Subsea Check Valve |

|

Location |

30 meters under seawater |

|

Medium to Handle |

Light Crude Oil w/ salt water traces |

|

Piggable |

Yes |

|

Locking: |

Valve is able to lock at full open position |

Project reference: Salvador subsea oil pipeline